New Automatic Vacuum Block Molding Foam EPS Machine

The SPB200-600/LF/LZ eps polystyrene block foam machinery(Vertical) is a efficient equipment, this helps to mould more blocks within a short period of time. Available in different specifications and sizes, our blocking moulding machines are sustained and sturdier.

Main Features

The blocking moulding machine has all advantages including the features of DZ/DF type block molding machine

Machine structure:

a. The polystyrene moulding machine mould is welded onto strong rectangular tubes and steel plates to ensure a high strength frame,for more safety.

b. All block mould frames are processed by heat-treatment,to release the welding pressure and avoid deforming. The EPS automatic shape moulding machine can maintain good performance and produce for you for a long time.

c. After heat treatment,all mould frames are processed by sand blasting treatment to get rust prevention,so that the under coat and finishing coat are greatly improved for anticorrosion performance. The EPS styrofoam block moulding machine is long life.

d. Adopts three German gauges and safety valve for increased protection, the EPS styrofoam block moulding machine will be water pressure and steam many testing, ensure the machine more stable and safety.

Steam system: Three ball valves,comparing one big steam valve,saves 20% steam,with ISO-standard butterfly valves,greatly improve the stability and long life of the thermocol block moulding machine.

Control system:

a. Adopts PLC (Mitsubishi) and touch screen (Schneider), these make the thermocol block moulding machine easy to operate.

b. The thermocol block moulding machine equipped with material level sensor for control filling.Process.Block cooling is controlled by foam pressure sensor,which senses the filling,heating,cooling and opening of the block mould.The whole process is automatic.

c. Vertical frame type:Less space occupied,with good drainage performance,reducing moisture content of block.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

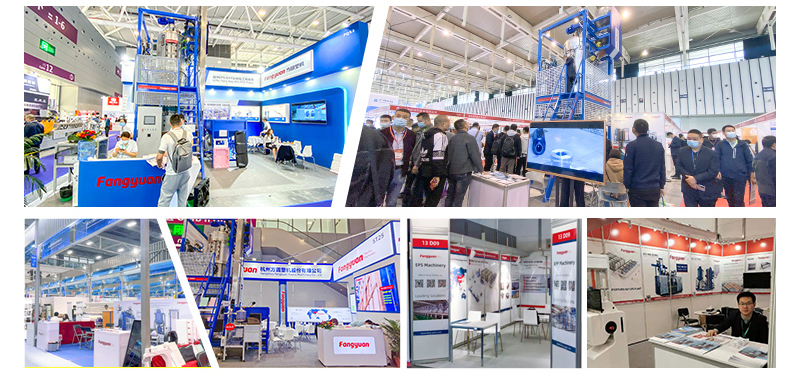

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

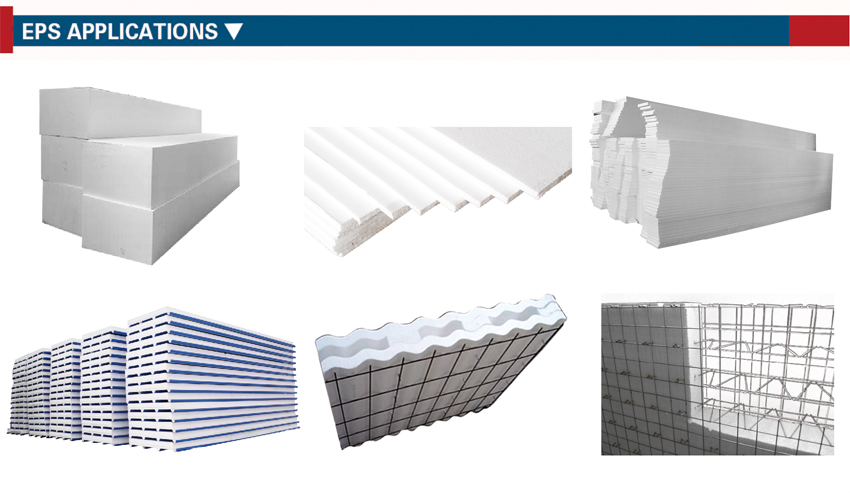

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts.

ch

ch English

English