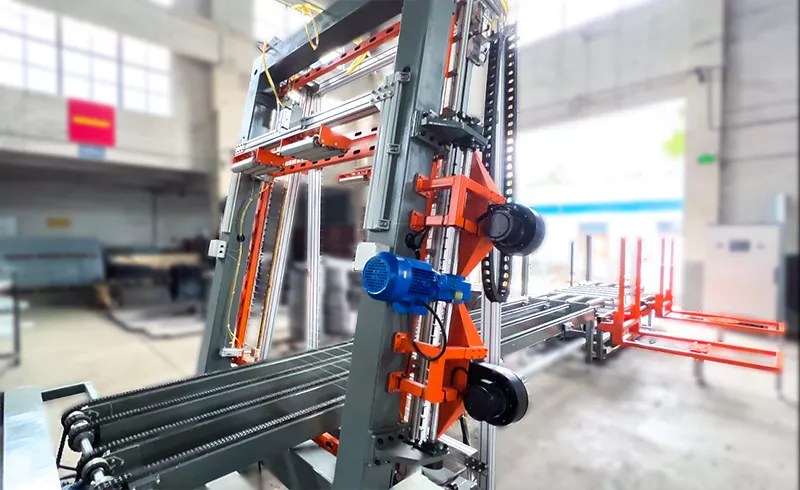

EPS Expandable Polystyrene Foam Vacuum Forming Block Moulding Machine

The 200-800DZ DF EPS Block Machine is designed to produce high-quality EPS blocks efficiently and reliably. This eps machine is available in various specifications and sizes, ensuring durability and versatility.

Main Features:

Machine Structure:

The mold of the eps machine is welded onto strong rectangular tubes and steel plates, providing high strength and additional safety.

All block mold frames are heat-treated to release welding stress, preventing deformation and ensuring the longevity of the eps machine.

After heat treatment, the mold frames undergo sand treatment to prevent rust, and undercoat and finishing coat are applied to enhance anticorrosion performance.

The eps machine is equipped with three German gauges and a safety valve for multi-safety protection. It undergoes rigorous testing with water pressure and steam to ensure stability and safety.

Steam System:

The eps machine features three ball valves, which save 20% steam compared to a single large steam valve control system. ISO-standard butterfly valves further improve stability and extend the life of the eps machine.

Control System:

The eps machine uses a PLC (Mitsubishi) and touch screen (Schneider), making operation intuitive and user-friendly.

Equipped with a material level sensor for precise filling control and a foam pressure sensor for block cooling. The entire process, including filling, heating, and cooling, is automatically controlled by the PLC.

Note:

An economical type is available, but the Germany gauge, foam pressure sensor, ISO-standard butterfly valve, and three-valve steam system are exclusive features.

ch

ch English

English