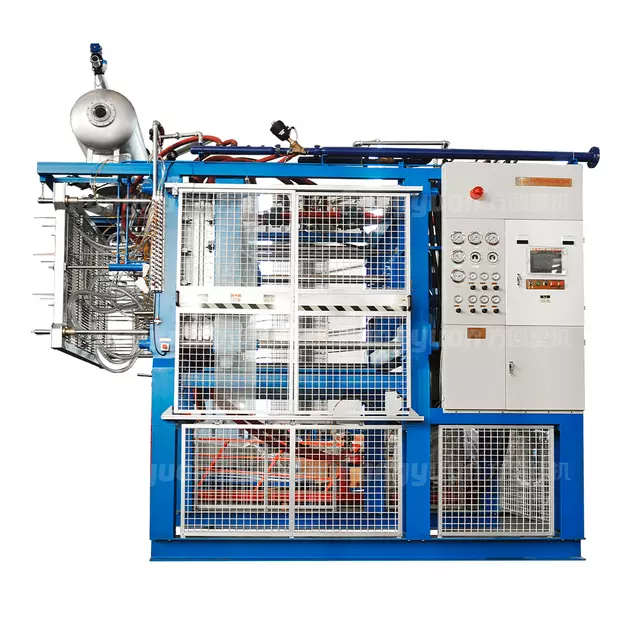

ETPU Machine :China ETPU machine - ETPU Moulding Machine->ETPU Foaming Machine, PV 850, Vertical ETPU Moulding Machine, Vertical ETPU Moulding Machine, Horizontal ETPU Moulding Machine. Energy-Efficient ETPU Moulding For Popcorn Soles · European standard EPS machines, specialized in high-end EPS/EPP/ETPU shape moulding machines,An ETPU injection molding machine is a specialized piece of equipment designed for processing expanded thermoplastic polyurethane (ETPU machine) materials, a type of E-TPU machine elastomer. This ETPU foam machine manufacturing machine is commonly used in industries like footwear, automotive, and sports equipment due to the lightweight, durable, and energy-absorbing properties of ETPU machine. Utilizing technologies such as E-TPU foam injection molding and E-TPU bead molding, the machine is capable of creating products with excellent rebound and flexibility. ETPU molding technology is especially popular in the production of ETPU footwear, cushioning systems, and other high-performance items. Additionally, this type of equipment can also handle tasks like E-TPU machineextrusion and E TPU machine pelletizing, making it a versatile solution for thermoplastic polyurethane processing.

Recycling and Environmental Impact of EPS MachineIn addition to production, EPS machines also play a role in recycling. Foam materials can be processed through recycling granulators, reducing waste and promoting sustainable manufacturing practices. EPS machines are often equipped with these auxiliary components to ensure that leftover materials are reused, contributing to a more eco-friendly production cycle.

Importance of Correct EPP Machine InstallationTo achieve optimal performance from the EPP machine, correct installation is critical. This includes ensuring that the machine is properly grounded and that all components are aligned and securely fastened. Proper setup of the EPP machine is essential for smooth operation and consistent product quality. Operators must follow all installation guidelines and conduct regular checks to avoid any potential issues during production.

Importance of Proper ETPU Machine SetupTo ensure optimal performance, the ETPU machine must be correctly installed and set up before use. This includes ensuring that all components, such as the heating and molding systems, are securely in place and that the machine is properly grounded. Correct setup of the ETPU machine is crucial for preventing operational issues and ensuring that each production cycle runs smoothly and efficiently.

How EPS Machines Work in Detail

What is an EPS Machine?

An EPS Machine is a specialized device used to manufacture expanded polystyrene foam products. It is designed to transform raw polystyrene beads into various foam items, making it essential in industries that require lightweight, insulating, and protective materials.

Key Components

Presets: Initial foaming of raw material.

Sheet and Automatic Forming Machines: Shaping and forming the foamed material.

Cutting Machines: Trimming and cutting the final products.

Recycling Granulators: Processing waste material for reuse.

Auxiliary Equipment: Supporting the production process.

Types of EPS Machines

Intermittent Preset: Suitable for small-scale operations.

Continuous Preset: Ideal for large-scale production.

Automatic Shape Molding Machines: Available in series like SPZ100-200 A/B, SPZ100-200 T, SPZ100-200E, and SPZ100-200 FHS.

Production Process

Foaming: Raw material is foamed using steam or electric heating.

Molding: Foamed material is transported into the plastic molding machine.

Shaping: Products are shaped and molded.

Trimming and Drying: Final products are trimmed and dried.

Use Cases

Electronics Packaging: Protects sensitive electronic devices.

Agricultural Packaging: Used for fruits, vegetables, and aquatic products.

Construction Materials: Insulation and protective packaging for building materials.

Benefits for Businesses

Versatility: Can produce a wide range of foam products.

Efficiency: Automated processes enhance productivity.

Cost-Effective: Reduces waste and optimizes material usage.

ch

ch English

English