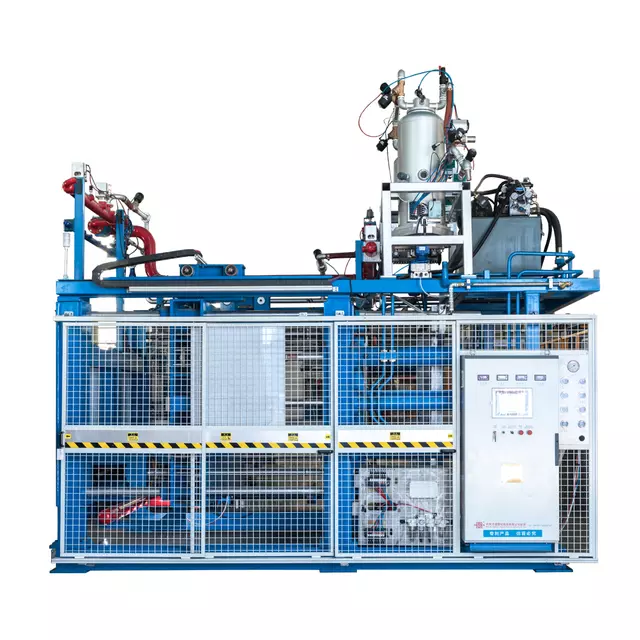

The ETPU Machine PV 850 is an efficient and flexible semi-automatic foaming machine designed for midsole production. It offers cutting-edge features that ensure energy-efficient, high-quality manufacturing.

With the ability to produce 2-3 pairs of midsoles per cycle, this machine increases manufacturing throughput.

Operators can adjust production settings for flexible mold use, allowing for sampling or full-scale runs.

The ETPU Machine supports a variety of mold sizes, making it compatible with industry-standard designs.

Single-cavity mold crack adjustment solves weight issues for small-sized midsoles, ensuring consistent quality.

The machine allows for dual-density midsole production and carbon fiber board integration, broadening its capabilities.

An optimized steam heating system reduces steam loss, speeding up production while lowering costs.

The machine works with all types of ETPU popcorn raw materials, providing versatility in production.

ch

ch English

English