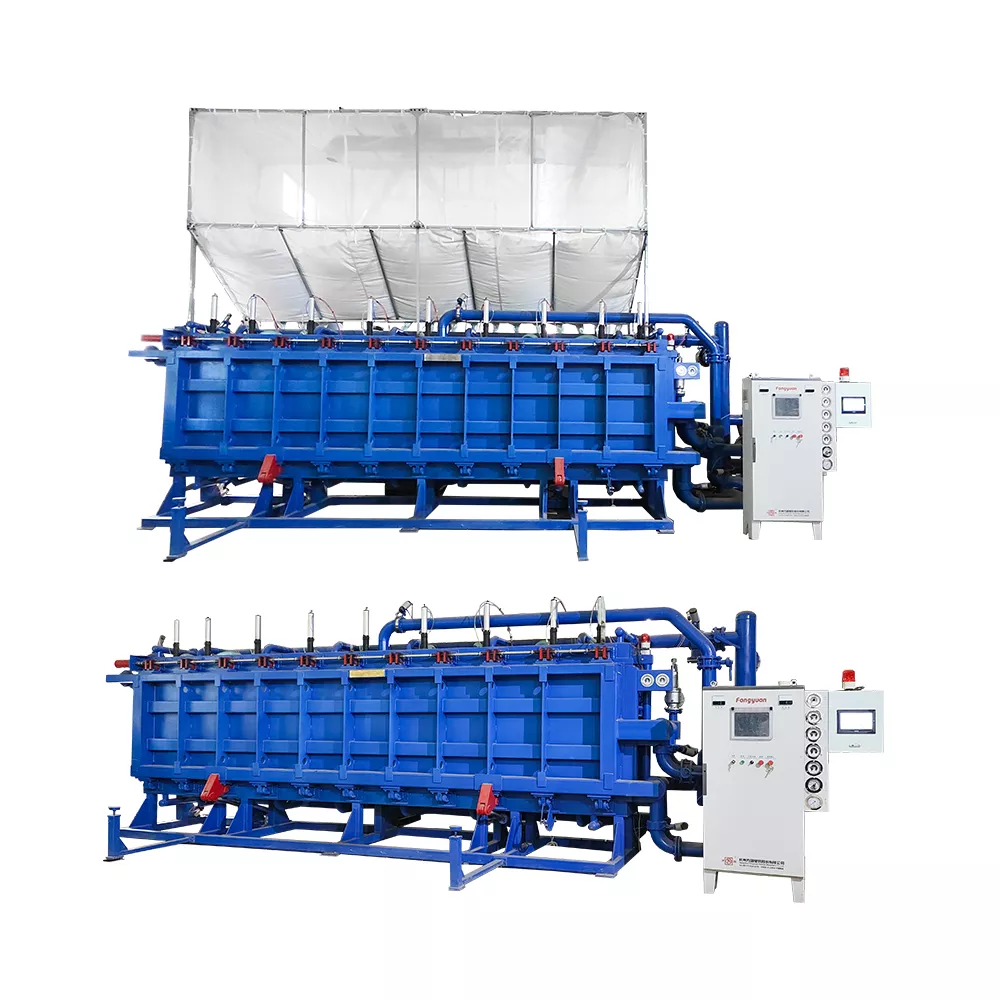

High-Precision EPS Moulding Machine with Energy-Saving Features

The EPS shape moulding machine is designed for high-precision production with advanced heating and pressure control systems, making it ideal for large-scale operations.

Main Advantages:

Efficient Heating Process: The proportional control steam valve and balance valve ensure pulse heating, maintaining consistent and stable temperature control.

Precise Pressure Control: With an electro-pneumatic proportional valve, operators can precisely control the steam inlet, ejection, feed, and compression pressures.

Energy Savings: The machine's efficient energy recycling system significantly reduces vacuum power consumption and shortens the vacuum cooling time, leading to energy-efficient operation.

Moisture Control: The moisture content of the EPS products remains below 7%, even with high-temperature demoulding (at 75°C).

The EPS machine provides consistent quality, increased efficiency, and reduced environmental impact.

ch

ch English

English