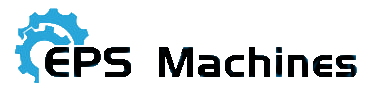

High-Efficiency EPS Shape Moulding Machine with Low Steam Consumption

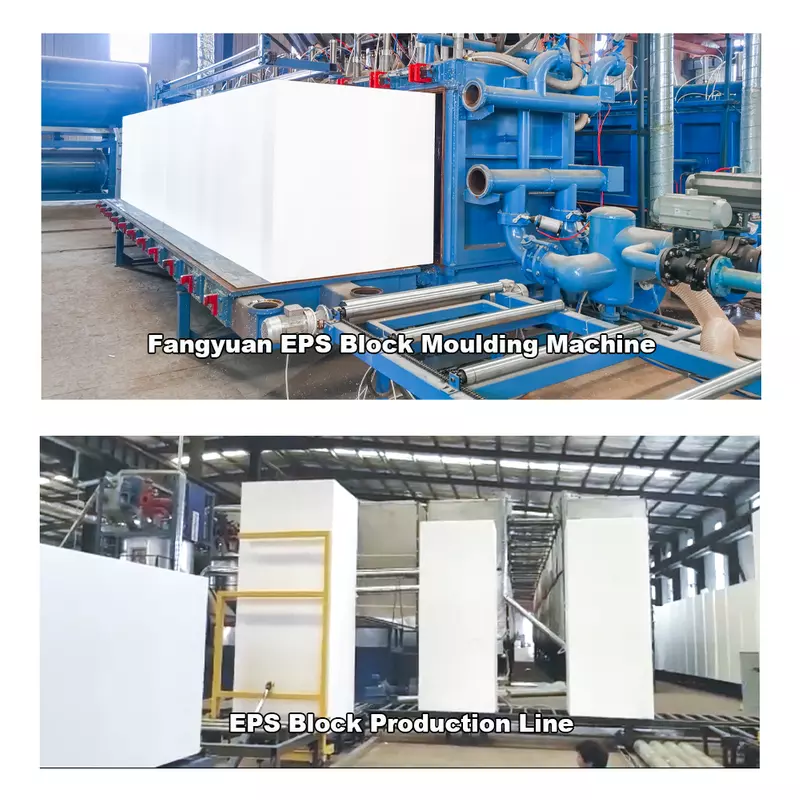

The EPS automatic moulding machine is designed to minimize steam consumption and enhance production efficiency, making it perfect for continuous, high-output operations.

Key Features:

Proportional Steam Control: The proportional control steam valve and balance valve offer precise pulse heating, optimizing the steam supply and reducing overall consumption.

Pressure and Energy Management: Electro-pneumatic proportional valves allow for precise control of steam inlet pressure, ejection pressure, and feed pressure, reducing energy waste.

Improved Vacuum System: The efficient energy recycling system ensures a 50% reduction in vacuum power consumption, shortening the cooling period and ensuring high-quality EPS products.

Stable Cavity Pressure: Pressure sensors provide accurate feedback, ensuring stable molding pressure throughout the production cycle.

This EPS machine delivers both energy savings and high production quality, making it an ideal choice for sustainable manufacturing.

ch

ch English

English